Izakhelo zeModyuli yeSolar

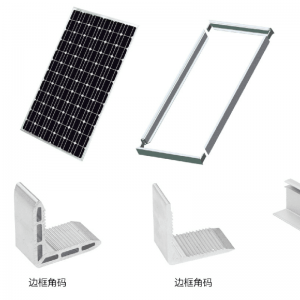

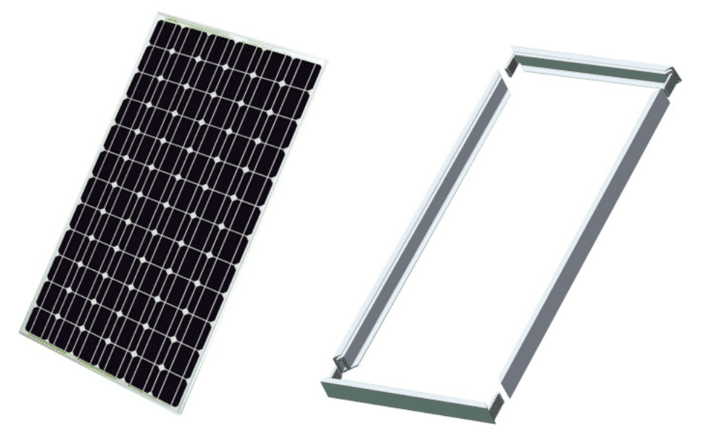

Inkcazo

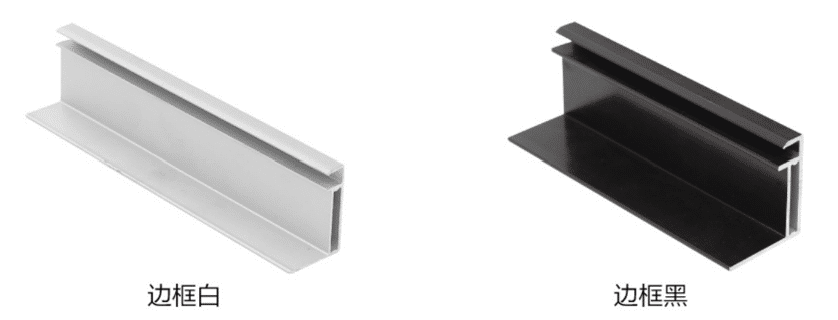

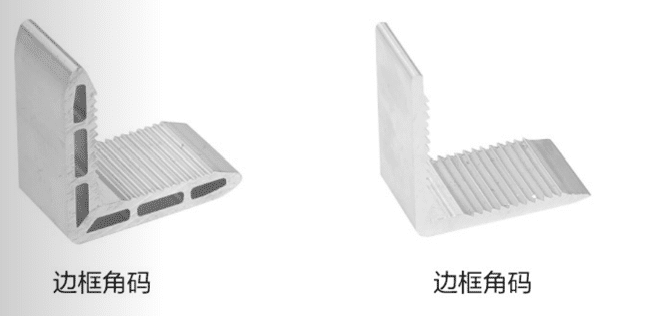

Izakhelo zemodyuli ziyafumaneka ukuba zenziwe ngokwesicelo sakho, iGoodsun ikwabonelela ngoyilo lwethu oluqolileyo olukhethwe nguwe.Kunyango lomphezulu, sibonelela ngesilivere kunye ne-anodization emnyama kwimfuno yakho eyahlukileyo.

Iimpawu zeMveliso

1. Anti urhwaphilizo 2. High tensile kunye uzinzo 3.Agqwesileyo ukutsala amandla

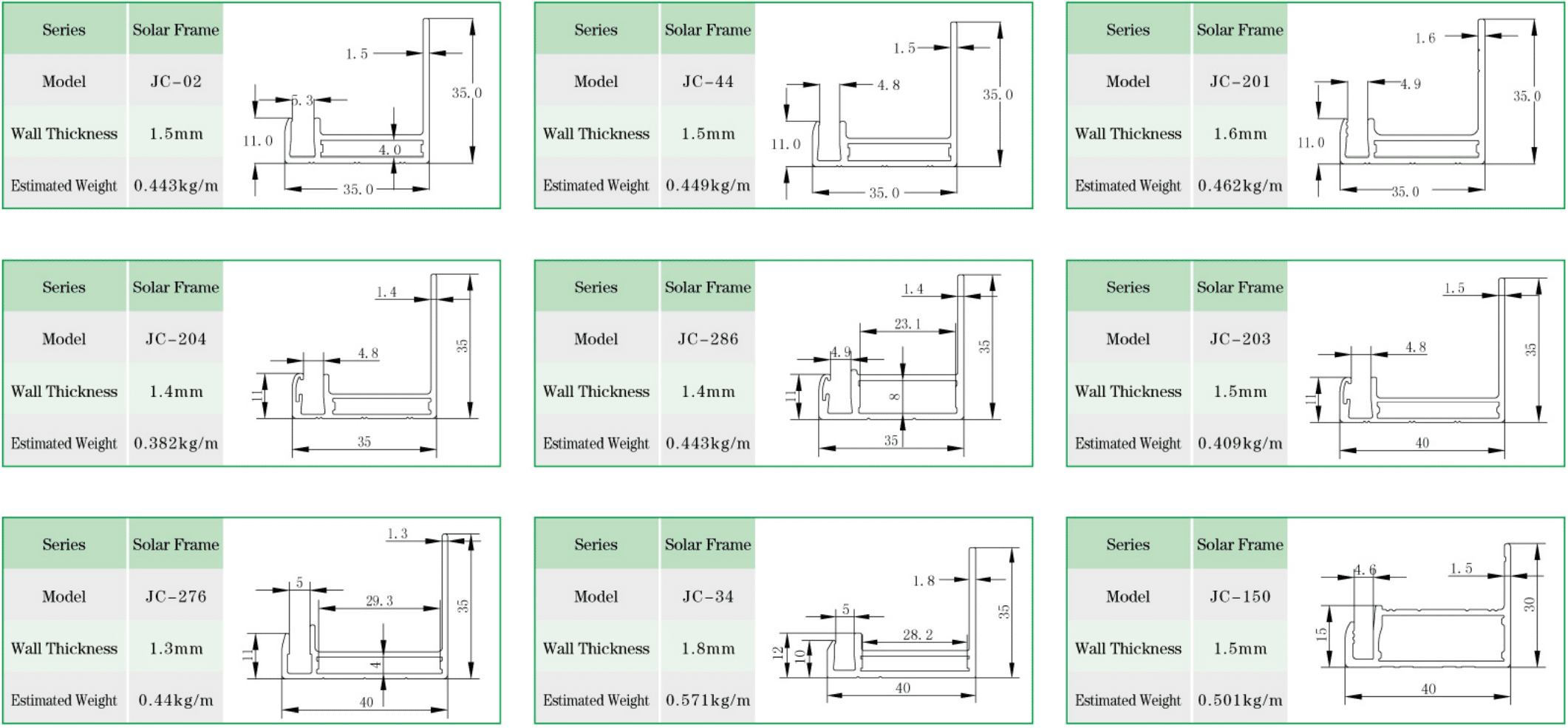

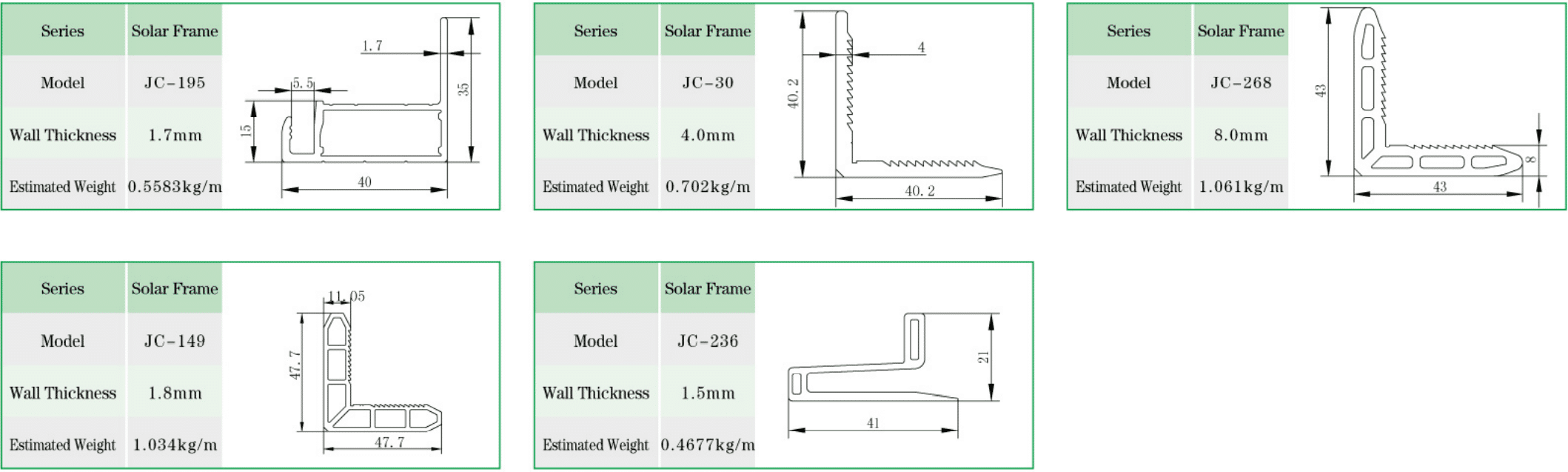

IParameter yobuGcisa

| Izinto eziphambili | AL6005-T6/AL6063-T5 |

| Umbala | Iyafumaneka ukulungiselela |

| Unyango lomphezulu | Anodization, Powder ukutyabeka |

Iifoto zesampula

Iifoto zetyala

Iinkcukacha zeMveliso

Iinzuzo zeMveliso

Inzuzo kaGoodsun kwitekhnoloji nakwimveliso

Ibonakaliswe ngoyilo olufanelekileyo noluthembekileyo, ukuhanjiswa ngokukhawuleza, ubunzima obulula, izibiyeli zethu ziyilwe ngokwethu ngokupheleleyo.Njengenyathelo lokuqala, iziko lethu le-R&D lisebenzela umzobo wezibiyeli, likhetha izixhobo ezifanelekileyo ezisekwe kwipropathi yazo, emva koko lishushu likhuphe iimilo ezahlukeneyo zecandelo lemveliso yealloy ekhanyayo, ekugqibeleni lifezekise izibiyeli ezahlukeneyo ngokusika, ukubethelwa, ukugrumba, ukugoba, ukwenza machining. ngokusebenzisa izixhobo ezilungiselelwe wena.

Ukubunjwa kweCu, i-Zinc, i-Al, i-Si njl zenzelwe ngokufanelekileyo kwi-alloy metal yethu, enegalelo kumandla aphezulu, ubunzima obuphezulu, ukuqina okuphezulu kweemveliso zethu.Ubunzima bayo yi-1/3 yentsimbi, kwaye iyasebenziseka kwakhona kwaye ihambelana nokusingqongileyo, ilungele ngakumbi uphahla oluhlaziyiweyo kunye neeprojekthi ezidadayo, kunye neendawo ezineemeko zothutho ezinzima.Ngaphezu koko, i-alloy inokusebenza kakuhle kwe-conductivity yombane, ekwazi ukuqhuba umbane obuthathaka ovela kumandla ombane.

FAQ

1. Isebe lemveliso lihlengahlengisa isicwangciso semveliso xa lifumana umyalelo wemveliso owabelwe okokuqala.

2. Umphathi wezinto eziphathekayo uya kwindawo yokugcina izinto ukuze afumane izinto.

3. Lungisa izixhobo zokusebenza ezihambelanayo.

4. Emva kokuba zonke izixhobo zilungile, abasebenzi beworkshop yemveliso baqala ukuvelisa.

5. Abasebenzi bokulawula umgangatho baya kwenza ukuhlolwa komgangatho emva kokuveliswa kwemveliso yokugqibela, kwaye ukupakishwa kuya kuqalisa ukuba kuphumelele ukuhlolwa.

6. Emva kokupakisha, imveliso iya kungena kwindawo yokugcina imveliso egqityiweyo.